- Home

- Products

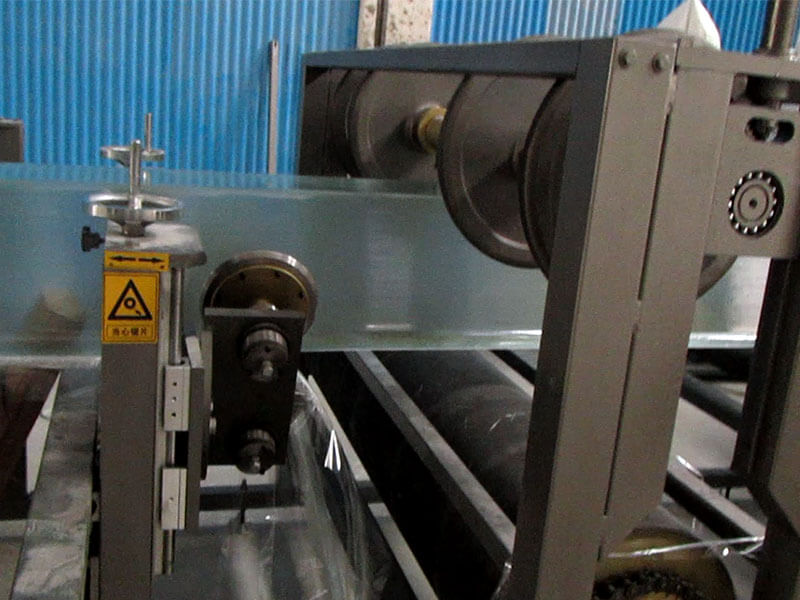

- FRP water draining gutter production line

- SH1500 multi-function production line for FRP products.

SH1500 multi-function production line for FRP products

- Product Description

For FRP water draining gutters, feeding troughs for animals and dual-layer gelcoat sheets. Continuous production process. Various kinds of profiles of FRP gutters and troughs can be produced with one machine.

- Product Advantages

Upper and lower gelcoat unit is equipped for making gelcoat layer on products. Non-wind-blowing type gelcoat heating system prevents PET film from trembling, ensuring good quality of gelcoat layer Pulse-free resin metering system, accurate metering, width range of adjustment, available for metering resin with powder add-ins. Impregnation platforms with independent heating and temperature control system, making impregnation fast in different ambient temperature, increasing production speed effectively. PLC based operating system, Qua-screen HMI, all production figures can be set in HMIs, and production running automatically, operators can be qualified upon short training. Three independent-control curing and forming zones, special programmed PID algorithm, fast preheating, low power consumption, increasing curing degree of finished products, ensuring high quality. Temperatures in curing zones up to 120℃, not only matching normal temperature curing system(MEKP system), but also being proper for high-temperature curing system(CHP system). Six inside cycles of hot wind in three zones with 6 ovens gives a smaller cycle of hot wind, making control of temperature more exact and uniform. High-temp centrifugal blowers instead of axial flow fans, ensuring long working lift and low failure rate. High accuracy automatic synchronous cross cutting. National-standard steels are adopted for high performance and stability. National-standard cables(communication cables with dual-shield layer) are adopted for smooth communication and stable performance. On-line remote debugging is available based on internet connection.

- Performance

| Operators Required | 4-6 operators |

| Max. Running Speed | 3-8 m/min |

| Optimum Production Speed | 4-7m/min (depends on the sheet thickness and operators' skill) |

| Finished Sheet Width | Maximum width-1.5m |

| Finished Sheet Thickness | 0.8-4mm |

| Wave Height of Finished Sheet | Max. 400mm (Gutters) Max. 130mm(sheets) |

- Basic Technical Parameters

| Power Input | Three-phase /AC380V /50Hz/3P+1N+1PE (can be customized upon local electricity system) |

| Power | Total power: 180kW. Running power: 55kW. Peak power: 140kW |

| Length | 75-80m |

| Width | 4-6m |

| Height | 4.5m |

| Weight | 28MT |

- Products List SH1500 Series SH2200 Serie SH3000 Serie FRP water draining gutter production lineFRP flat vehicle panel production line Film embossing machine Machines for pultrusion FRP products

- Contact Us Address: No.11-3 Leshan Road, Economic and Technology Development Zone, Qinhuangdao City, Hebei Province, China. Wechat: +86-18503359919 WhatsApp: +86-18603352012Tel: +86-18503359919Mod: +86-335-3508855E-mail: admin.intlsalesdept@songhe.cc

- About Us Qinhuangdao Songhe Technology Co.,Ltd./ Qinhuangdao YiYang Machine Manufacturing Co., Ltd. was established in 2017 in a beautiful coastal city Qinhuangdao. It’s nearby Beijing with very convenient transportation.

Songhe is focus on researching, designing and producing automatic FRP products forming production lines.

English

English Español

Español Русский

Русский